Wire Enamels

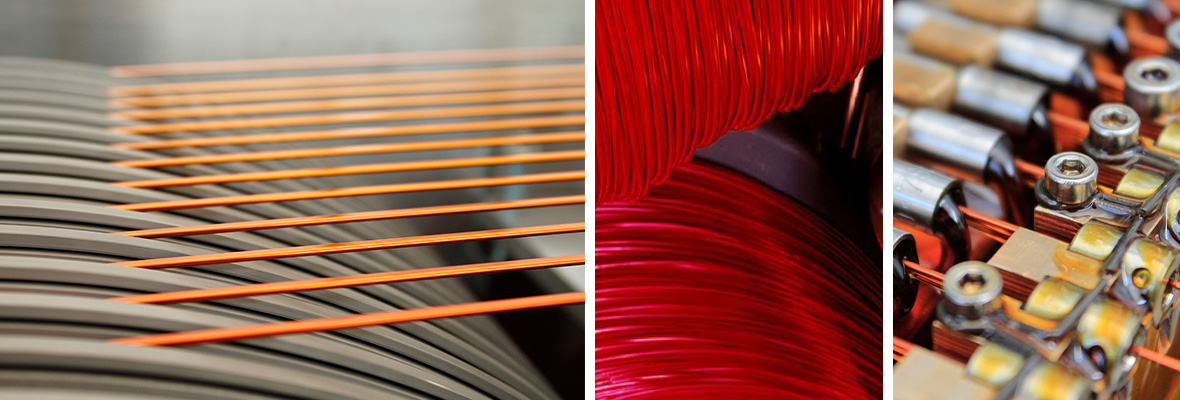

ELANTAS PDG, Inc. manufactures high-performance enamels for use as magnet wire coatings. They are coated on the surface of copper or aluminum wires and cured to form an electrical insulation film.

Magnet wire enamels, in general, consist of polymeric resins dissolved in organic solvents. Apart from the basic electrical insulation requirement, wire enamels provide high thermal and mechanical stability, flexibility, moisture resistance and long service life of the insulation, depending on the end-use application.

Wire enamels are used where an electrical insulation of windings is necessary. The main end use application areas are transportation, automotive, household appliances, motors, transformers, industrial electronics or power generation.

Depending on your individual requirements, we offer different search and selection functions to help you find the appropriate material. The listed products are an extract from our actual product portfolio. More products are available on request.

Do you need further information about our wire enamels? Please get in touch with us. We are looking forward to your email to info.ELANTAS.PDG@altana.com.

To download a Technical Data Sheet or a Material Safety Data Sheet, please click here.

| Enamel Type | Diameter Range (AWG) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Tangent Delta °C | Thermal Index °C | Comments |

| Terester® C 966-36 HVL | 12-14 | 35.5 ± 1 | 600-900 | 200°C | 378 | 160°C | 203 | General purpose, cresol-rich solvent system |

| Terester® C 966-36 HVA | 12-28 | 36 ± 1 | 600-900 | 200°C | 381 | 160°C | 203 | Excellent Techrand windability |

| Enamel Type | Diameter Range (AWG) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Tangent Delta °C | Thermal Index °C (ASTM D-2307) | Comments |

| Terester® C 966-36 HVL | 8-24 | 25 ± 1 | 2000-3200 | 240°C | 380 | 260 | 230 | General purpose |

| Terester® C 966-36 HVA | 8-24 | 30 ± 1 | 1000-1700 | 240°C | 380 | 265 | 230 | Self-lubricated with internal lubricant |

| Enamel Type | Diameter Range (AWG) | Solids | Viscosity CPs mPa.s (25°C) | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Solderability sec / °C | Tangent Delta °C | Thermal Index °C | Comments |

| Solderite® M 932-E-22 Red | 32-48 | 23 ± 1 | 30-45 | 175°C | 243 | 4/360 | 148 | 159 | General purpose, fast-running |

| Solderite® Q 1380-26 | 28-44 | 25 ± 1 | 50-75 | 200°C | 254 | 4.5/360 | 180 | 195 | High performance, pinhole-resistant |

| Enamel Type | Diameter Range (AWG) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Tangent Delta °C | Thermal Index °C (ASTM D-2307) | Comments |

| Formvar C 8359-23 | 8-28 | 23 ± 1 | 1700-2900 | 175°C | 230 | 112 | 124 | General purpose, oil-resistant, flattenable, high-solids |

| Enamel Type | Diameter Range (mm) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Tangent Delta °C | Thermal Index °C (ASTM D-2307) | Comments |

| For class 240 Application | ||||||||

| Ultratherm® 828-15 | 0.32 – 1.63 | 15 ± 1 | 5500 – 7500 | 260°C | > 500 | 280 | 241 | High temperature, excellent flexibility |

| Enamel Type | Diameter Range (AWG) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Tangent Delta °C | Thermal Index °C | Comments |

| Teramide® A 3737-40 | 12 – 24 | 39.5 ± 1 | 1200 – 1800 | 220°C | 370 | 185 | 202 | High performance |

| Enamel Type | Diameter Range (AWG) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Solderability sec / °C | Tangent Delta °C | Thermal Index °C | Comments |

| Polyurethane, imide-modified | |||||||||

| Solderite® Q 1380-26 | 28 – 44 | 25 ± 1 | 50 – 75 | 200°C | 254 | 4.5/360 | 180 | 195 | High performance, pinhole-resistant |

| Enamel Type | Diameter Range (AWG) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Wire dia. | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Tangent Delta °C | Thermal Index °C (ASTM D-2307) | Comments |

| THEIC-modified polyester | |||||||||

| Terester® C 966-36 HVA | 12 – 28 | 36 ± 1 | 600 – 900 | 1.02 | 200°C | 381 | 160 | 203 | Excellent Techrand windability |

| Enamel Type | Diameter Range (AWG) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Wire dia. | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Tangent Delta °C | Thermal Index °C (ASTM D-2307) | Comments |

| THEIC-modified polyester | |||||||||

| Terester® C 966-36 HVA | 12 – 28 | 36 ± 1 | 600 – 900 | 1.02 | 200°C | 381 | 160 | 203 | Excellent Techrand windability |

| Enamel Type | Diameter Range (AWG) | Solids Content % (2g-2h-200°C) | Viscosity CPs mPa.s (25°C) | Wire dia. | Heat shock NEMA 20% Stretch (Pass 3d) | Cut through NEMA °C | Tangent Delta °C | Thermal Index °C (ASTM D-2307) | Comments |

| THEIC-modified polyester | |||||||||

| Terester® C 966-36 HVL | 12-28 | 36 ± 1 | 600-900 | 1.02 | 200°C | 381 | 160 | 203 | Excellent Techrand windability |

| Polyvinylformal, modified | |||||||||

| Formvar C 8359-23 | 8-28 | 23 ± 1 | 1700-2900 | 175°C | 230 | 112 | 124 | General purpose, oil-resistant, flattenable, high-solids |